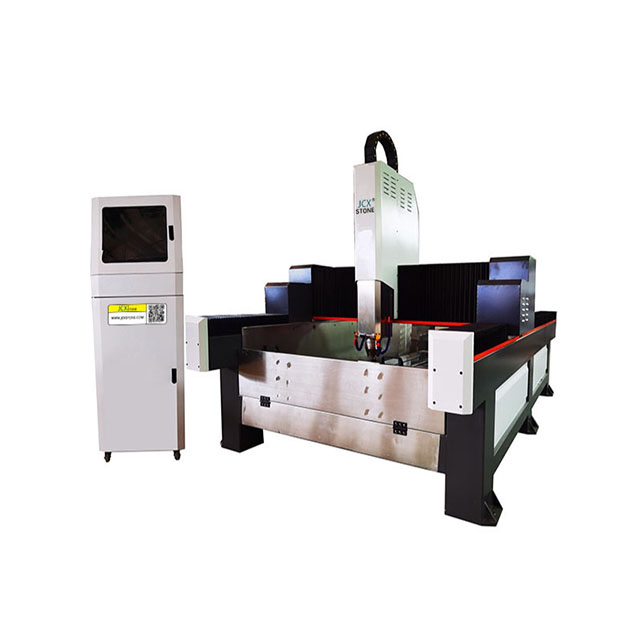

Ⅰ. Product Parameters

|

X axis working size

|

1000mm

|

|

Y axis working size

|

2000mm

|

|

Z axis working size

|

650mm

|

|

Max working speed

|

5m/min

|

|

Max engraving speed

|

3-5m/min

(according to different material and engraving depth)

|

|

· Repositioning Accuracy

|

±0.05mm

|

|

Cooling

|

Water cooling

|

|

Spindle power

|

5.5KW water-cooled spindle /380V high-speed operation wear-resistant and waterproof

|

|

Water proof

|

Sheet metal spray waterproof, retractable waterproof curtain

|

|

Table

|

Cast iron rotary platform, bearing without deformation

|

|

Water spout

|

Two-way cooling, can control the water

|

|

Drag Chain

|

High flexural and flexural engineering chain

|

|

Spindle speed

|

0-24000rpm/min

|

|

Stone fixing method

|

Splint fixed, flexible adjustment according to the size and thickness of the plate

|

|

Transmission

|

X/Y/Z axis Taiwan TBI precision ball screw

|

|

Guide rail

|

National standard 30 square rail, wear-resistant, high precision, long life

|

|

Inverter

|

5.5KW overload and overvoltage protection

|

|

Drive

|

Ori servo drive

|

|

Control system

|

DSPA18 four-axis handle control

|

|

Cabinet

|

Independent cabinet to prevent interference and dust

|

|

Software

|

Wen Tai, JD carving

|

|

Support format

|

G code,BMP、PLT、AI、DXF and so on

|

|

Voltage

|

380V/50Hz Three phrases Four lines

|

|

Tools

|

Marble granite ball tools, straight tools, diamond tools (sharp tools) , total 10pcs

|

|

Tools holder

|

ER25 6/8/9

|

|

Pressure plate

|

Fixed stone 8 sets

|

|

Water pump

|

2 pcs, lift 5 meters (copper head)

|

|

Hexagon wrench

|

3 pcs

|

|

Spare supplies

|

Machine commonly used screws, hex screws, synchronization belt, bucket, toolbox

|

|

· Machine dimensions

|

2670*3185*4100mm

|

|

Weight

|

About 2800kgs

|

|

Packaging

|

Separate plastic file package

|

Ⅱ. Samples

Ⅲ. Machine Feature

This machine is made of heavy materials, compact bed and durable bed without deformation. The whole machine processes the guide rail surface and drilling through a large five face milling machine. The key parts of the machine choose imported excellent accessories, with high machining precision, large production capacity and higher degree of automation. Imported high-precision ball screw transmission is adopted, and the lead screw is highly heat-treated.

The wear resistance is more durable and the service life of the whole machine is prolonged. This equipment is equipped with high-end, servo control, fast and stable operation.

Ⅳ. Company Introduction

Our company name is Beijing YanDiao CNC Machine Co.,ltd,

Mainly engaged in the design, research and production of the CNC machines since 2010. Factory,over 80,000 M2 workshop , more than 600 working people.

Ⅴ. Our Advantage

- We have our own machining workshop . All machines frame, gantry and Z axis are made by our own workshop. In this way, we can ensure our good quality and lower the cost .

- We can design and produce according to customer’s requirements. (including machine structure , type , color , spare parts and so on )

- We can make OEM. ( with customers’own logo on the machine )

- We have rich experience for exporting, we will prepare well all customs documents and CO for making customs successfully.